ARE YOU

LOOKING FOR A ‘REAL’ SPHERICAL WAVE HORN?

ONLY A TRACTRIX HORN MAY CALL ITSELF A REAL SPHERICAL WAVE HORN.

Our axisymmetrical tractrix horns with a desirable axis and 180% emission,

ideally support the natural, spherical diffusion of the musical signal.

The physically calculated shape of the horn is by cut-off frequency and finite

tenor shorter and smaller in diameter than other horn shapes. This explains why

the spherical wave horns, in comparison to other horns, sound so authentic and

differentiated. This is particularly evident in the reproduction of voices and

instruments and is also very favourable with regards to the transparency with

realistic deep scaling and three dimensional reproduction.

A short history of the spherical wave horn

The architect and engineer Vitruv already in the 1st century BC had the idea to

use a spherical wave horn as a reinforcing sound funnel. He was the first to

describe sounds as movement of the air and used this knowledge when building

amphitheatres in order to achieve a natural reinforcement of actors and

musicians on stage.

Only some 1800 years later did the physicist Christiaan Huygens, 1693, manage

to mathematically calculate a tractrix curve, which plays a fundamental role in

hyperbolic geometry. The tractrix is the curve function, in which for each

tangent the section between the contact-point and the coordinating

axis is constant, and only the shape of the tractrix horn enables the formation

of the spherical wave form, which is created naturally in the process of

release from the mouth of the horn.

The choice

of the Tractrix horn flare profile was influenced by many things, including:

J Dinsdale, “Horn Loudspeaker Design” in Wireless World 1974, concluded, “…both

theoretical considerations and very careful listening tests by the author and

others tend to support the claims that the tractrix is the optimum horn

contour.“

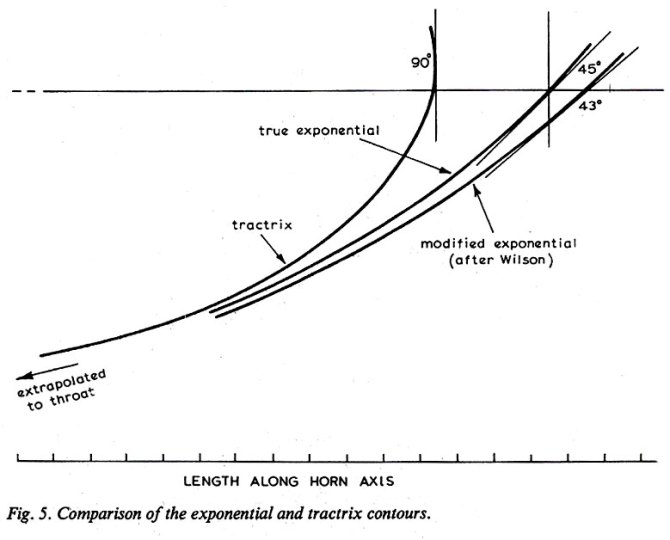

Dinsdale claimed that the Tractrix contour “…combined the excellent low

frequency characteristics of the exponential curve with the spherical wave

propagation characteristics of a conical horn“. (Bruce Edgar, “The Tractrix

Horn Contour”, Speaker Builder, 2/81)

From “Horn Loudspeaker Design”, by J. Dinsdale, Wireless World, Mar 1974.

The Tractrix profile “launches spherical waves that can yield excellent stereo

imaging effects” (Bruce Edgar, “The Edgar Midrange Horn”, Speaker Builder,

1/86)

“The tractrix’s reduced length compared with conical or exponential horns of

the same frequency range gives the advantage of being smaller than other horn

contours.” ( Bruce Edgar, “The Tractrix Horn Contour”, Speaker Builder, 2/81)

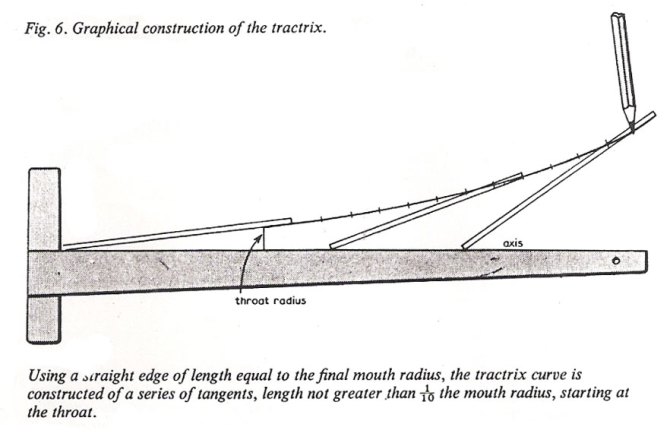

The Tractrix curve is generated from the mouth (not from the throat like most

other horn profiles ) and so, mouth-room termination is more gentle, more ideal

& more efficient, in air-pressure terms. The Tractrix horn mouth terminates

when curve tangent is 90° to the horn axis. “Keele found that beaming effects

of conical and exponential horns can be minimized by doubling the flare at the

mouth.” ( Bruce Edgar, “The Tractrix Horn Contour”, Speaker Builder, 2/81)

Dr Bruce Edgar (Edgar Horn previously) has been responsible for much modern

development in horn loudspeaker implementation, understanding and remedying

colourations and addressing shortcomings that were typical of horn loudspeakers

previously.

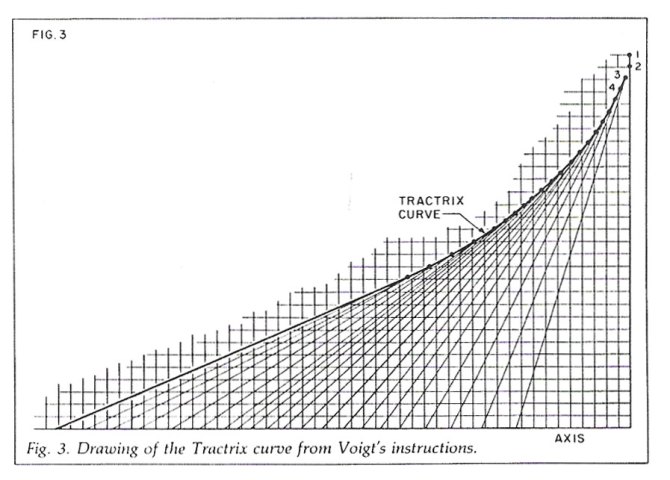

Dr Bruce Edgar’s drawing – from his “An Interview with P.G.A.H. Voigt – Pt

1″, Speaker Builder, 3/81.

From “Horn Loudspeaker Design”, J Dinsdale, Wireless World, Mar 1974.

Some history:

The Tractrix horn contour was developed by the German-born, British

audio-inventor P.G.A.H. Paul Voigt in 1926 (patented in 1927).

We should pay some respect to Paul Voigt. Just a few of his innovations:

He designed a loudspeaker driver in the mid-1920s, with ultra-light paper cone

& ultra-high magnet strength coil (originally electromagnet field coil) –

specifications still currently marketed by Lowther and others. Voigt invented

the twin-cone loudspeaker, which was licensed to Wharfedale and Goodmans.

Voigt patented the Tapered Quarter Wave Pipe (TQWP) enclosure concept for

loading speakers. He developed horn loudspeakers for domestic and cinema use.

Manufacture

The development and production of our tractrix horns from resonance-poor cast

stone requires substantial development and knowhow. Therefore these horns are

not comparable with other horns available on the market, regardless of price.

All original models and casts for the manufacture of our horns, as well as all

horns, are made on the premises. This allows us to ensure that every horn is

the same. If required we can also produce OEM.

On the following pages you will find our spherical wave horns which are

calculated physically according to the tractrix function.

If you would like to choose a tractrix horn for a particular driver, please use

the Search function.

Should you

have any questions, please first consult our FAQ.

Should your

driver not be available, please contact us, and we will provide expert advice.